To an organization to be successful in the current competitive world and with highly competitive industrial norms, it should be able to sustain in the market with a continual growth and meanwhile increase their profits to run the business smoothly and to develop itself. Nowadays with the high inflation, all the general public try to reduce their expenses hence this make all businesses to control the market prices of their products or services in spite of the thriving prices of resources, raw materials and over heads.

With many competitors in the market for the same product or

service, it is almost impossible to make profits with just increasing the sales

prices. To increase profits of a business, the company shall improve their

sales pitches, increase or maintain the good quality of the product or service,

reduce operational costs, improve delivery methods and options, and take more

actions to make profits meanwhile being sustained in the business.

TPM is now a blooming concept in the industrial world with

various concepts come in to one system to improve the productivity,

efficiencies and other profitable factors of an organization.

(Nakajima, 1988) the father of TPM considered this as

“profitable TPM” as reducing the cost of maintenance delivers automated increment

in profits. (Yamashina, 2000) Concluded that TPM could be a principal source of

profitability of a manufacturing organization.

TPM technically abbreviated as “Total Productive Maintenance” or “Total Productivity Management”. But with the work carried out in

the TPM concept finally give an organization a considerable increase in their

profits as this will reduce all types of operational costs and operational

losses by a considerable fraction including, sales, marketing, repair and

maintenance, downtimes, defects and rework, consumables, motions, logistics,

etc.

There are 3 major resultants which could be gained upon

successful implementation of TPM, which are “Zero Breakdowns”, “Zero

Defects” and “Zero Accidents”.

A general definition of TPM is “carrying out maintenance at the optimum cost”. An organization shall

carry out its maintenance at zero cost, a.k.a. does not carry out any

maintenance. And also, an organization may carry out its maintenance at any

cost a.k.a. carry out maintenance activities which are not required and which

are not with the machine manufacturer stated guidelines.

Both the systems will make the organization loose a huge sum

of money at the end as both those methods will fail the machinery at the end

or waste money which should not be expended.

Therefore, with the proper implementation of TPM concept in

failure prevention and machine maintenance activities, wasting of money can be

totally eliminated.

In TPM, a repair or a maintenance activity of a machine should

be carried out while the machine is at its running condition and or with the

shortest downtime possible. These are addressed in the “Planned Maintenance Pillar” which is one of the eight pillars of

TPM and which is an essential pillar. In Planned maintenance, all

deteriorations are identified and the most appropriate maintenance method for

each deterioration method is identified. The maintenance activities are

segregated in to two parts which one will sustain the best possible condition

of the machine and the other will improve the machine with kaizens.

All these maintenance activities done at the right time, with

right materials and equipment and with right expertise will reduce all types of

issues of the machines, resulting less or zero downtimes. Also, it will

eliminate any type of chronic losses and reduce the possibilities of creating

any sporadic losses in the machines.

These methods will also create space for programmable management

of the stocks of spare parts of machinery as the planned maintenance can

predict the spare part requirements and also will reduce the spare parts

consumptions.

Finally, proper planned maintenance will assist to create an

environment with “Zero Breakdowns”,

“Zero Defects” and “Zero Accidents” which are the 3 major

resultants of TPM. A planned maintenance will reduce any abnormal and

exceptional costs of machine repairs and maintenances with relate to spare

parts, man hours, machine availability, defective production and also any kind

of accidents which will directly affect the operational cost of the production

process.

There is another

indicator which is used to define the effects of TPM in a production process

which is in short named as “PQCDSM”

which denotes the words Productivity, Quality, Cost, Delivery, Safety and

Morale of a system.

TPM methodology is a very effective strategy for improving productivity and overall plant

efficiency. The lost production output due to material productivity, manpower

productivity, and tools productivity will be reduced and there will be a 1.5 to

3 times increment of OEE (Overall Equipment Effectiveness) and/or productivity

with TPM implementations. All losses

from the 16 losses which affect productivity are answered in TPM implementation

and with the elimination of those losses, the productivity and efficiency of a

system will improve which will give many ways of financial benefits to an

organization.

Quality has been considered as one of the utmost capable parameters

for creating the brand image. To make the product a “good quality product”, the

product must cater the customer requirement and should not have any kinds of

defects where the defect may cause the product to not to cater the customer

requirement during the indented operations.

(Feigenbaum, 1991) have clearly indicated that a TPM programme

can result in better product quality, improved manufacturing flow, and

reduction in operational expenses & losses, etc. TPM also aims at continual

and lifelong improvements in productivity & performance and therefore it

results in improving the monetary output of an organization in terms of market

segment and profits.

Therefore, to improve the quality of the product and reach

zero customer complaints and reworks, the product shall be with Zero Defects.

This can be done by eliminating rejection/rework, by avoiding mistakes in the

preparation of product, machines, methods, man power and also documentations.

In broader times, it means by meeting customer expectations so that there

should be no return of customer in any means. Customer complaints can be

reduced significantly and ultimately reach zero after the implementation of TPM

initiatives.

The “Quality

Maintenance Pillar” in TPM acts as the major constituent to control the

quality of the product with various control points in the processes, by

identifying the Quality components of each and every machine and their effects

to the product quality, etc. will create the requirement of fulfilling

countermeasures for identified issues related to deteriorations, cleaning,

lubrication, inspection, tightening, and repairing the machine and parts which

may create problems to the machine and the production process. Quality

Maintenance Pillar will decide the countermeasures which should be taken to

answer all issues and give required training to the machine operatives and

technicians to eliminate issues which could be created with each Q component.

Therefore, as stated before, improving not only the quality of

the product, but also quality of other 3Ms which are Man, Materials and

Machines will directly affect the revenue of the company hence increase the

profitability of the organization.

TPM has been a very fruitful in terms of improving operational

performance of organizations. TPM claims to have an optimistic influence on cost indicator as per (Feigenbaum, 1991).

It is because all eight big losses are monitored thoroughly to improve the OEE

and this expressively increases the manufacturing yield within the same time interval.

Also, the average operational cost will come down with higher manufacturing

yield with the same inputs.

There are many costs involved in a product which finally

decide the production unit cost and the sales price of a product, which

ultimately decide the profit created from the product. TPM concept helps to

reduce the manufacturing cost by 30% to 50% through reducing operational and

maintenance cost, inventory carrying cost and cost of communication, etc.

Delay or imprecise deliveries

will have a negative impact on customer satisfaction and also the organization’s

brand image. CCFOT (Customer Cases

Fill On Time) or the Fill Rate is a

parameter which the customers look for in a good product, secondly to the price

and quality. To make the customers happy and content, they need a precise,

faster and a timely delivery method

of any product.

There can be various reasons for the delivery delays such as delay

in production processes, supplier inconsistencies, delay in payments to

suppliers, delay in packing, delay in procurement process, delay in information

transfers, which ultimately cause the delays in logistics and then the final

delivery. Other than those, external delays like customs formalities, government

inspections, and system failures can also affect the on-time delivery.

TPM helps to deliver 100% goods on time to the customer. It

can be achieved by minimizing the delays in production processes, logistic activities,

delivery methods, and any of the support functions as stated above. A proper

delivery is an activity which will increase the customer satisfaction and hence

increase the loyalty of the customers.

There are several losses defined in TPM 16 losses structure

which will affect the delays in delivery. They are breakdown losses, adjustment

losses, quality and defects losses, yield losses, management losses, logistics

losses and line organization losses. Eliminating these losses will create an in-time

production output hence eliminate delays in product deliveries.

Product inventory is also an additional cost to an

organization in relate to maintaining the stocks in good conditions, the stores

space consumed by the inventories and the depreciation of goods. TPM will be

able to reduce the product inventory at least by 50% which will reduce the

operational costs relate to product inventory handling which will also improve

the delivery which reduce the costs incur.

Safety is one of the major factors considered in TPM with targeting

a Zero Accidents environment inside an organization. TPM concept will create an

accident-free zone area by ensuring safety while working on machines, safety in

material handling, safety in packaging, safety in transportation, and safety in

almost everything.

Inside an organization, the 4Ms which are Man, machines,

Methods and Materials are contributing to the safety of the activities, health

of the humans and pollution of the environment. Almost all the accidents happen

due to unsafe acts and unsafe conditions of humans and activities. Incorrect workplace

designs, operator’s carelessness, unsuitable design of the equipment and tools,

damaged utensils, lack of effective protection guards for equipment, lack of

fire preventive systems, hostile working conditions such as high noise and air

pollution are some of the instances for unsafe acts and unsafe conditions.

The element Man is the most complicated factor in maintaining

safety and wellbeing in an organization. The equipment and materials can be

made safer to a favorable extent with various controls like safety sensors, Poka

Yoke, safety SOPs (Standard Operational Procedures) or Guidelines. The human aspect

must be mainly supposed in the incident and accident prevention.

Training will be done in the TPM implementation related to

safety, health, operational knowledge, etc simultaneously along with the other

training while moving towards Zero accidents concept. Fundamental principles of

TPM include guaranteeing equipment reliability, maintainability, preventing

human and eliminating accidents and environmental pollution.

Therefore, when the Safety and good health of the organization

and the people inside are considered, “Safety,

Health and Environment Pillar” in TPM

8 pillars structure plays the

major role in keeping the level of safety. In the SHE pillar, all hazards

related to occupational safety & health and aspects related to

environmental pollution are identified and counter actions are taken to

eliminate or reduce them. Safety related trainings are planned and carried out

to all employees within the organization through the SHE pillar activities and

ensure that all employees are knowledgeable in safety protocols in the

organization and all the employees carry out their work according to the given

SOPs and safety instructions.

The ultimate outcome of those activities will be zero

environment, safety and health related incidents / accidents which will eliminate

or reduce any costs incur for solving issues related to environmental impacts

and compensating for accidents occurred inside the organization or any health

issues created during the activities in the organization which will reduce the

company expenses at the end.

A successful organization will increase the morale of employees which will boost up

the organizational activities. TPM helps to boost up the employees of the

organization by making them participate in contributing a number of kaizens,

one-point lesson (OPL). The increased morale of employees will increase the

number of improvement suggestions by employees them selves by 5 to 10 times.

If the employees are extremely motivated and contented with

the work culture, they are more productive and engaged. If they are not

motivated, there is a more tendency of they are being less productive in the

organization. For inspiration and preserving the enthusiasm with optimistic

focus over the period, morale is an important TPM indicator.

Laying banners, publishing TPM newsletters, posting TPM

posters at specified locations, designing TPM slogans and displaying them can

create a constructive atmosphere and encourage employees to create a healthy

workforce culture. To improve the morale of the employees, giving motivation

awards to contributing employees in organizational events or meetings can be

carried out. The increased morale of employees will create a much better

results in production processes and improvement suggestions hence increase the

profitability of the organization as employees tends to work better and give

better results.

It is very important to measure and understand the method of

measurements of losses in the manufacturing process (Eswaramurthi,

2013). Losses can be divided into two categories named as “chronic losses and sporadic losses”.

Chronic losses

are usually small, hard to identify and complicated since they are results of

several simultaneous causes. Sporadic losses are more noticeable since the

deviations from the normal state are large.

Sporadic

losses occur irregularly and their effects are considered to lead to serious

problems with regard to large downtimes, high percentage of defects and maybe

also accidents. But there are chronic losses that result in the equipment frequently

but with smaller deviations from the normal state. With the time, those maybe

considered as normal and maybe neglected also. Although they are small, they

make large costs due to the fact that they occur repeatedly and continuously.

The

calculation of OEE can identify these losses whereby can be used to find

solutions for those losses hence reduce the operational costs. The major

contributing eight losses in the 16 losses structure can be identified in the

OEE calculation and all related chronic and sporadic losses should be answered

giving solutions to them with the TPM initiatives. This will increase the

productivity, efficiency and quality of the production process hence affect the

PQCDSM in a positive manner where again gives various kinds of financial gains

to the organization.

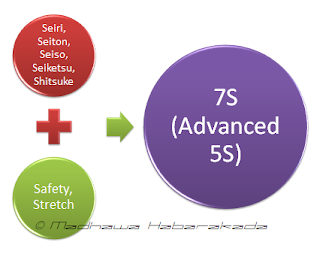

The whole concept of TPM structure is based upon the 5S principle where TPM defines a new

concept of 7S principle. Other than

the Seiri (Sort), Seiton (Set Locations), Seiso (Shine), Seiketsu (Standardize)

and Shitsuke (sustain), 7S is giving additional provisions to Safety and

Stretch (Improvements). The traditional

5S principle again have developed in to “Advanced

5S principle” where the final objective becomes profit, not

discipline.

The advanced 5S principle is supporting all the concepts of

TPM and nevertheless advanced 5S can cater the requirements of TQM (Total

Quality Management) and Lean (waste minimization) also. It is a cultural

changing tool and a standardizing tool which can target threes zeros defined in

TPM which are zero breakdowns, zero defects and zero accidents. it also can directly

involve to improve the PQCDSM in an organization. This will also give an

effective solution to the elimination of seven wastes which are excess

transportation, excess inventory, useless motions, higher waiting time, over

production, over processing and defective products. All these wastes are

financially loose points and elimination of those will reduce the costs of an

organization in a considerable way.

5S can make an organization a safe place and create work

friendly working environment. With the elimination of 4Ds (Danger, Dark, Dirty

and Difficulties), a workplace become safe to work with less cluttered

environment and with less ergonomic issues. It will assist to achieve zero

accidents and will improve the safety and morale of the employees. These two

achievements will affect the productivity of the employees hence reduce any

costs which may arise from unsafe work activities and accidents.

Elimination of useless things such as broken and unusable

machines, expired or unwanted materials, obsolete documents will eliminate the

risks of accidents relate to human safety, machine safety and process safety.

Also, unwanted things will take up warehouse space which is also a cost and

will be reduced with elimination of those expenses.

When the machines are clean enough and the level of cleaning is

maintained, the problems of the machines can be easily identified and any

improvements, modifications, corrections can be easily done. This will assist

the zero-breakdown concept and furthermore, this will reduce any deteriorations

hence reduce the costs for repairs and spare parts.

With implementation of visual management tools and visual

controls with 5S, the organization becomes much neat and tidy. The activities

which are carried out inside the organization would be much efficient and fast.

For instance, with the visual controls, all abnormalities in all activities can

be easily seen and identified where corrective/preventive actions could be

taken in advance without causing any adverse events to product, machine or

humans.

With the advanced 5S, people are motivated to give suggestions

for improvements and kaizens through the suggestions for improvements system.

The kaizens or suggestions will assist to improve the productivity or

efficiency of the processes and machineries. Also, the suggestions will answer

any kinds of sporadic or chronic losses inside the organization’s production

processes. Upon implementation of these kaizen suggestions, the OEE of the

processes will be increased creating a profitable condition for the

organization.

5s can maximize the profits and increase sustainability of an

organization by taking initiatives to enhance the productivity and efficiency.

Each and every company spend huge sum for giving training for their employees. In-house,

external, local, foreign training is given to employees to improve their

skills, capabilities, professional experience, etc. But in most cases those trainings are not effective and

do not improve the organization's profitability. (Habarakada, 2018)

There are various reasons which employers raise regarding the training they give to their employees. Training is being used as a motivational tool and in some cases, employers want to improve the employee profiles of the organization. There are companies who give generic training to their employees without selecting the suitable set of people for a specific training. The correct skills gaps are not identified by employers and the trainings are given blindly to selected employees irrespective of the requirements. (Habarakada, 2018)

There are various reasons which employers raise regarding the training they give to their employees. Training is being used as a motivational tool and in some cases, employers want to improve the employee profiles of the organization. There are companies who give generic training to their employees without selecting the suitable set of people for a specific training. The correct skills gaps are not identified by employers and the trainings are given blindly to selected employees irrespective of the requirements. (Habarakada, 2018)

With the TPM initiatives, the training will be highly targeted

and the required training will be given to the required employees only. The

skills gaps will be identified individually and the identified gap will be

filled with giving required and targeted trainings.

The internationally know ETHOS

process would be carried out on selection & identification, training and

evaluation of deliverables on trainings.

The correct training needs required inside the organization is

identified with the Loss Tree analysis and then with 4M analysis. Skill gaps of

each and every employee is identified via a detailed skills matrix evaluation

and a training needs identification system. The identified skill gap will be

answered by the training given to the employee. And finally, the employee will

be given target/project/KPI to improve, with the learnings he / she received.

This will improve the organization’s OEE and KPIs which will result in

reductions of costs, improvements in productivity and efficiency, etc.

With these all stated points, it is certain that TPM

implementation will improve the productivity and efficiency of machines and

processes, reduce all kinds of wastes in an organization, reduce costs of each

and every process, etc.

Therefore, it can be concluded that the TPM concept will

increase the profitability of an organization and hence, TPM can also be

defined as “Total Profit Management”.

There are only few points were discussed here considering the above finally stated fact, and this can be continued further giving much more reasons establishing the phrase "TPM stands for Total Profit Management".

REFERENCES

Nakajima, S. (1988)

Introduction to TPM: Total Productive Maintenance (preventative maintenance

series).

Yamashina, H. (2000)

Challenge to world‐class manufacturing, International Journal of Quality &

Reliability Management, Vol. 17 Issue: 2

Feigenbaum, A.V. (1991) Quality Control. 3rd Edition, McGraw-Hill, New York.

Eswaramurthi, K.G. (2013)

Improvement of manufacturing performance measurement system and evaluation of

overall resource effectiveness, American Journal of Applied Sciences.

Habarakada,

M. (2018) “Training is a Waste.

WHY?”, http://www.engineermadhawa.tk/2018/06/training-is-waste-why.html

TPM stands for Total Profit Management by MadhawaHabarakada is licensed under a Creative Commons Attribution-NonCommercial-NoDerivatives 4.0 International License.

Based on a work at http://engineermadhawa.blogspot.com/.

Permissions beyond the scope of this license may be available at http://engineermadhawa.blogspot.com/p/contact.html.

©

All rights reserved. 2018.07.16.

Unauthorized

copying and redistribution is prohibited. Proper Attribution should be given, provide

a link

to the license, and indicate if changes were made when adopting content of this

article.

By, Eng. Madhawa Habarakada. (AMIE-SL, BSc. Eng. (Hons))

http://engineermadhawa.blogspot.com/

Your comments are welcome.